It’s easy to see the importance of expertly branding products and their surrounding packaging to any brand’s success. In fact, your products and packaging may be the single most impactful brand touchpoint in your arsenal. They deliver lasting and meaningful impressions. So, it makes sense that deciding how to rebrand products and packaging is a major consideration for any rebrand, requiring substantial investments in research and development, manufacturing, and advertising to end users.

The process of transitioning your products and packaging for a rebrand is anything but straightforward. There are many factors to consider. These include regulatory and legal considerations as well as your firm’s tolerance for cross-branding and the impact of your particular manufacturing and sales cycles on your overall rebranding timeline. Here are some key insights to help you plan appropriately.

10 steps to brand implementation success

Here are 10 steps to take to ensure that your new brand is implemented into the marketplace correctly.

Start by bringing together all the necessary stakeholders

Rebranding your label or product is never as easy as simply applying the new branding to your existing designs.

For one thing, products and packaging can be highly regulated, requiring international certification for both the manufactured product and the shipping information. (This is especially relevant for electronics, consumables, and healthcare products.) There are also legal considerations. If your organization’s legal entity is changing, for example, that will likely trigger a whole slew of legal requirements that will impact your products and packaging. In addition, there are almost certainly technical implications to transitioning your products and packaging. This could involve everything from updating the back-end systems that feed information to your website and label-printing software to re-tooling the molds used to manufacture products.

Successfully transitioning your products and packaging will require high-level coordination and collaboration between a number of functional teams. Your quality, regulatory, legal, IT, and manufacturing teams will all play a role. Your product team doesn’t necessarily know precisely what part each of the other functional groups might play. Your first order of business is to bring all of these internal groups together. You must then figure out who is responsible for what, the sequencing of each task, and who is in charge of approvals. And all of these decisions must map realistically to the overall rebranding budget and timeline for your company.

How to rebrand your products: align your rebrand timeline with product manufacturing and sales cycles

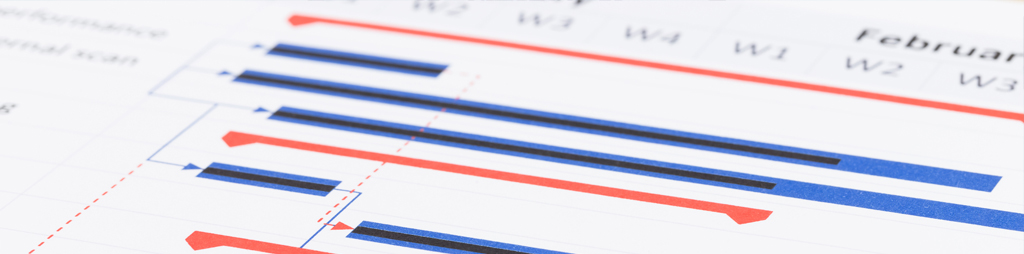

Your plan for transitioning products and packaging will relate in a very direct way to your overall timeline for launching your rebrand. It’s crucial that you start with a detailed understanding of the manufacturing and shipping cycles at your facilities. You’ll also need to have an understanding of how much stock is on hand.

To start, you need to have a detailed understanding of how often your products are manufactured and how long they typically take to sell. Most companies have a mix of faster and slower-moving products, meaning that product cycles aren’t necessarily in sync.

Understanding what those different cycles are and where each product falls within them helps you estimate when the new brand will hit the marketplace. For example, if you manufacture 75% of your products every three months and typically sell though those products in six months, you know that your end users will see the new brand within nine months.

This information is key to determining how to time your public brand launch and when to initiate marketing and communication efforts around individual products as they transition, too.

Determine your organization’s threshold for cross-branding

Theoretically, planning for a hard rebrand launch across your line of products is the most appealing approach. However, it’s rarely the most practical (or financially prudent). The reality is that some degree of cross-branding – meaning that a single product and/or its packaging carries both the old logo and new branding for a period of time—is almost always inevitable. The nature of product and packaging manufacturing and selling cycles, as well as the fact that companies do not stop production during the rebrand planning phases, makes this especially true. Part of your planning process will involve assessing the impact and acceptability of having cross-branding packaging in market — and for how long. Your answer will depend on the following factors:

- Your manufacturing cycles. Given the varying production timelines between products, it would be almost impossible to coordinate a hard rebrand rollout across your entire product line all at once. In many cases, it’s sensible to transition the fastest-moving and highest-visibility products first.

- The amount of existing stock on hand and its value. In cases where inventory levels are high, it may be necessary to repackage or relabel stock.

- Legal requirements. Legal considerations (especially if your legal entity is changing) may play a role in dictating your cross-branding threshold or timeline for fully transitioning your product line.

Depending on your particular circumstances, the timing for fully transitioning your products to the new brand could be as short as a few months or as long as several years.

Rebranding as an opportunity to rethink your products and packaging

Finally, don’t forget that a rebrand represents a unique opportunity to reconsider your products and packaging from the perspective of your end users. Now may be a useful time to solicit consumer feedback about what your users like and don’t like about your existing product line, or to introduce a more environmentally friendly or cost-effective approach to your packaging.

At BrandActive, we guide our clients through all the complexities of transitioning their products and packaging via a customized plan. Want to learn more about our approach? Check out our case studies.